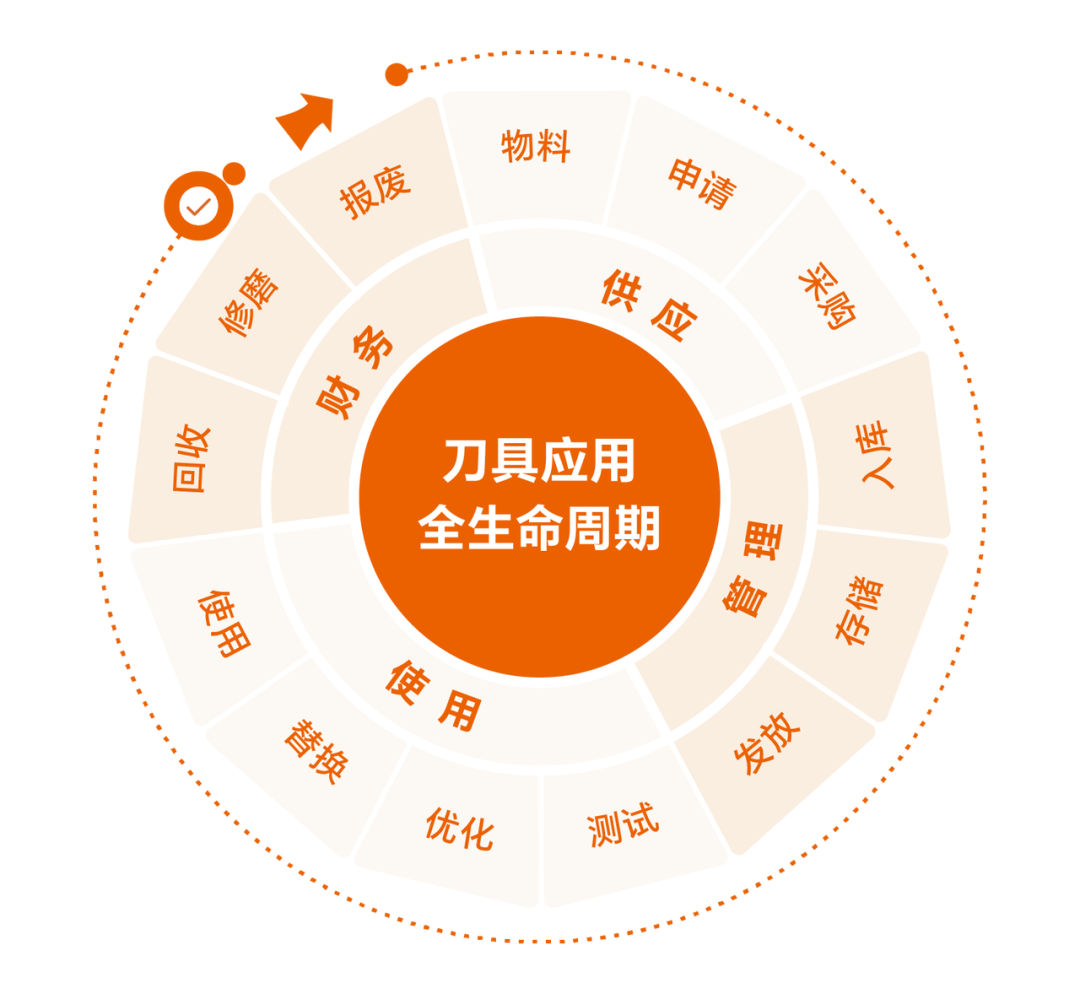

In the machining industry, tool management not only affects machining efficiency, but also directly affects production costs and product quality. Traditional tool management often relies on experience, which can lead to tool waste, improper use, and untimely replacement. Through the application of a full lifecycle management solution for cutting tools, Nuoer aims to assist enterprises in achieving maximum efficiency of cutting tools and achieving the goal of "maximizing the use of tools".

The selection of cutting tools is related to machining efficiency and quality. Nuo Erwei establishes detailed performance profiles for each tool through systematic data support, covering indicators such as cutting force, machinable objects, and machining degree, to accurately evaluate the performance of the tool. Through Nuowei's tool management and operation system, enterprises can scientifically select tools based on their actual performance data, avoiding the errors that may arise from traditional empirical rules.

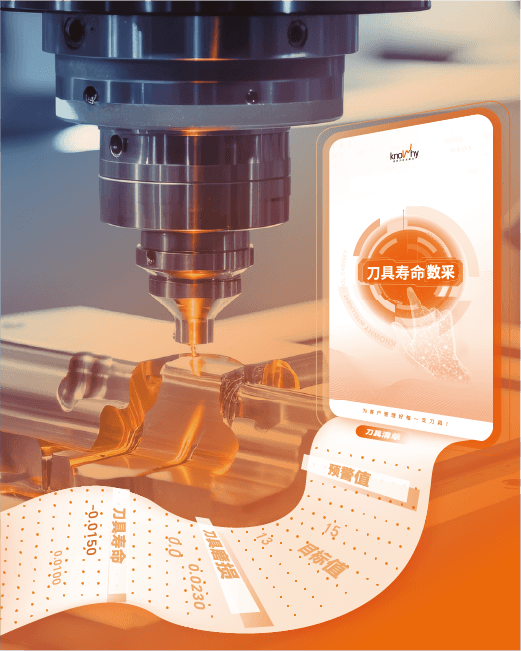

The use of cutting tools also affects production efficiency. By recording various data of cutting tools, including cutting performance, wear status, etc., Nuo Erwei helps enterprises comprehensively understand the actual performance of cutting tools. These data not only help enterprises make more reasonable decisions during the use of cutting tools, clarify the tool's lifespan, ensure that the tools are replaced or ground at the right time, avoid excessive wear and unnecessary production stoppages.

The recycling and reuse of cutting tools is an important step in reducing costs. Through the combination of software and hardware, Nuoer aims to first enable enterprises to utilize the "trade in" recycling mechanism to reduce waste and loss. Then, by recycling, sorting, grinding, and reusing, the utilization rate of grinding tools can be improved, and corresponding usage rules can be established to avoid premature waste or excessive grinding. This not only extends the overall lifespan of a knife, but also reduces procurement costs for enterprises.

Nuo Er Wei tool management is not only a tool, but also an intelligent decision support system. By accumulating a vast amount of data during the machining process of cutting tools, the system can analyze the machining performance of the tools under different environments and parameters, including the average actual life, which provides data support for future tool procurement. Enterprises can prepare a tool procurement plan in advance based on the results of data analysis to ensure the efficient operation of the production line.

Conclusion

Are you tempted by such refined tool management?

Welcome to contact us for an immediate experience

Maximize the efficiency of your cutting tools!

+86 512 6938 3264

+86 512 6938 3264