In the daily production of the machining industry, tool selection and process are important factors that affect efficiency, cost, and product quality. Traditional tool selection relies on drawings and experience, while the process flow is recorded in paper drawings, which are cumbersome to update, untimely, and difficult to accumulate technical knowledge. Nuo Erwei's standardized solution for tool data and process data has broken this dilemma. Through digitization and standardization, it helps enterprises improve production efficiency, reduce management costs, and achieve more intelligent management.

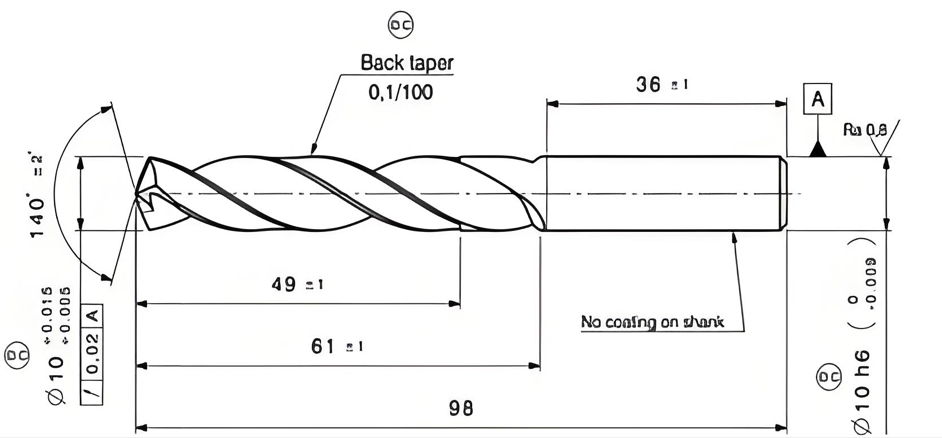

In traditional tool management, technicians usually choose tools based on experience and drawings, but this method has significant limitations. The performance differences of different brands and models of cutting tools may not be directly noticeable to the naked eye. Traditional tool drawings can only provide limited information, making it difficult to make quick and accurate choices.

Through digital standardization, Nuoer provides a detailed description of each tool using 140 key parameters and inputs them into the system to create a unified tool database. This not only makes tool data more comprehensive and intuitive, but also provides engineers with more scientific selection criteria, avoiding the problem of excessive reliance on personal experience.

Advantages:

Standardized management: Each tool has a complete digital file, transparent parameters, and comparable performance.

Accurate recommendation: Based on the machining scenario, the system automatically recommends suitable cutting tools to ensure the best machining effect.

Cost effectiveness optimization: By comparing the performance and prices of different brands of cutting tools, help enterprises find more cost-effective options.

With the help of the system, engineers no longer need to rely solely on drawings and experience to select tools, but can quickly find and choose the most suitable tool through a unified digital platform.

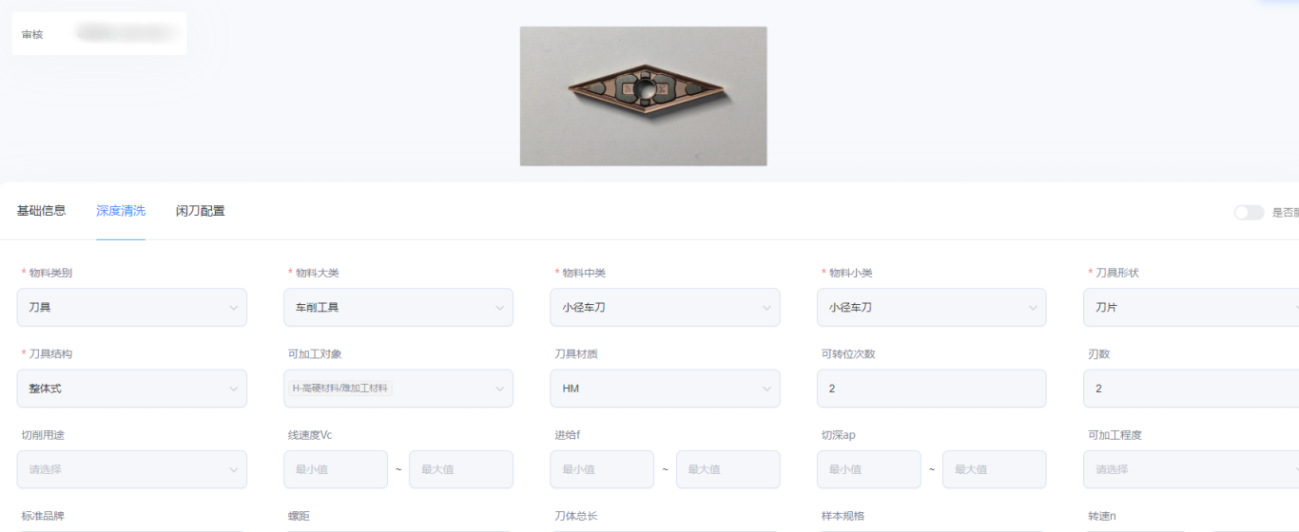

Nuo Er Wei Tool Management Operation System Tool Information (Part)

Application case:

Usually, purchasers need to make multiple inquiries to obtain information on tool prices and performance. This not only consumes a lot of time, but also increases labor costs. Through Nuo Er Wei's tool management system, all tool data has been digitized and entered. Purchasing personnel can directly query cost-effective spot goods in the system, reducing the tedious operation in the price comparison process and saving a lot of time.

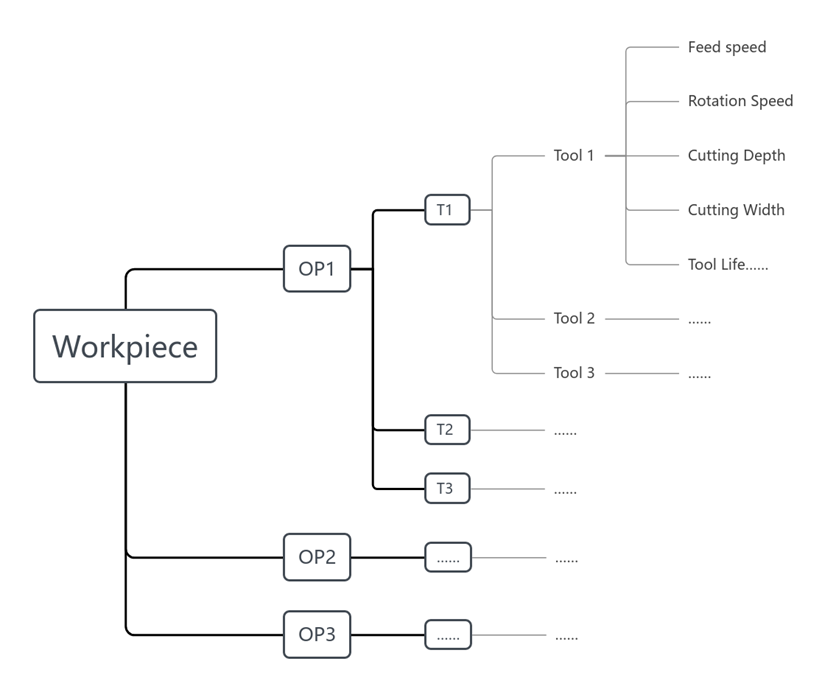

Similarly, traditional process management relies on a large number of paper drawings and manual records, which are slow to update and difficult to trace. Whenever there is a change in technical personnel or product requirements, the relevant process solutions are often difficult to inherit and adapt quickly.

Nuoer has achieved standardization of process data by integrating process BOM through 120 key parameters. All operational processes, technical experience, and processing parameters are entered into the system in digital form for easy and quick access and updates. This not only greatly improves the accuracy and real-time performance of process data, but also solves the problems of information loss and difficult technical precipitation in traditional methods.

Advantages:

Flexible management: All process data is stored in the system, and modifications and updates can be recorded in real-time to ensure accuracy and traceability of information.

Efficient reuse: When similar products need to be processed, previous process plans can be directly reused to avoid designing from scratch and save time.

Technical accumulation: With the replacement of technical personnel, all process data can be saved for a long time, avoiding technical loss caused by personnel turnover.

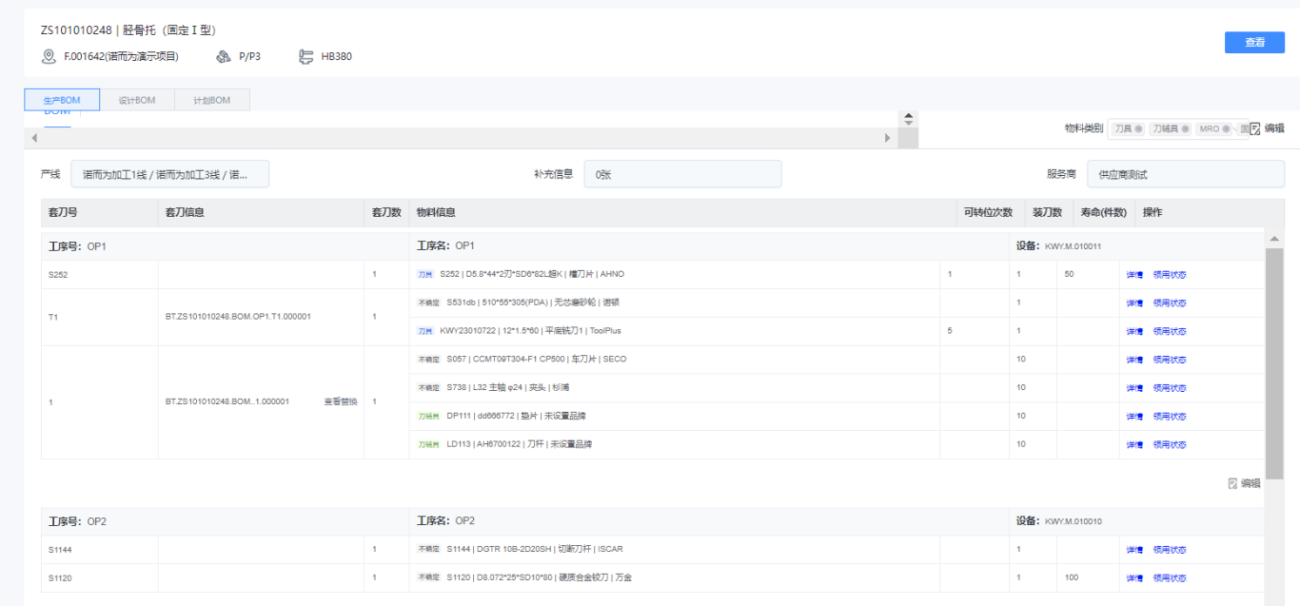

Process Information of Nuo Er Wei Tool Management and Operation System (Part)

Application case:

At the production site of a certain machining enterprise, process personnel usually need to flip through thick paper drawings to find suitable processing solutions. New employees need a mentor to guide them for a short period of time to learn and get started, which is inefficient. But by standardizing and storing all process plans on a digital platform, employees only need to search for relevant parameters in the system to quickly find process plans that meet the requirements, and can flexibly adjust them, improving work efficiency and consistency.

The standardized solution for cutting tools and process data not only helps enterprises solve pain points in traditional management methods, but also provides a foundation for their digital transformation. Through digital tools and process data, enterprises can achieve:

Accurate management of cutting tools: We help companies scientifically select cutting tools through standardized data and recommend the best solution based on the machining scenario.

Efficient management of processes: Standardization of process data improves the speed and accuracy of information flow, enhancing the traceability of the production process.

Reduce management costs: By digitizing the management of tools and processes, enterprises can reduce the time cost of manual price comparison, release more energy, and improve overall operational efficiency.

To summarize: Digitalization leads the future of intelligent manufacturing

Standardizing data is the foundation for moving towards intelligent manufacturing, and the key to the future lies in how to apply these standardized data to more practical machining scenarios. Through continuous exploration and optimization, Novartis will continuously expand the application boundaries of digital tool management, helping enterprises achieve greater breakthroughs in production efficiency, cost control, and technological accumulation.

The road to digitization has just begun, and there are more possibilities. Stay tuned.

+86 512 6938 3264

+86 512 6938 3264