October in Beijing — the direction is reaffirmed.

The Fourth Plenary Session of the 20th CPC Central Committee has concluded, proposing:

A more complete institutional system for promoting high-quality development

Accelerated development of new quality productivity

Advancement of new-type industrialization

From a macroeconomic perspective, this is top-level design. For manufacturing enterprises, it signals that the test of the times has changed again.

Over the past decade, Chinese manufacturing has moved from “quantity accumulation” to “quality leap.” Next, at a higher coordinate system, one question arises:

What truly defines high-quality manufacturing?

01 Manufacturing’s “New Quality” Lies Not in Machines, but in Data

Some say “new quality productivity” is the integration of new technologies, new models, and new industries. But in each factory, its starting point is often a small thing — seeing the numbers once ignored.

In tool management, these numbers hide in every tool change, every wear, every issuance. Once overlooked, now they are a gold mine for lean improvement.

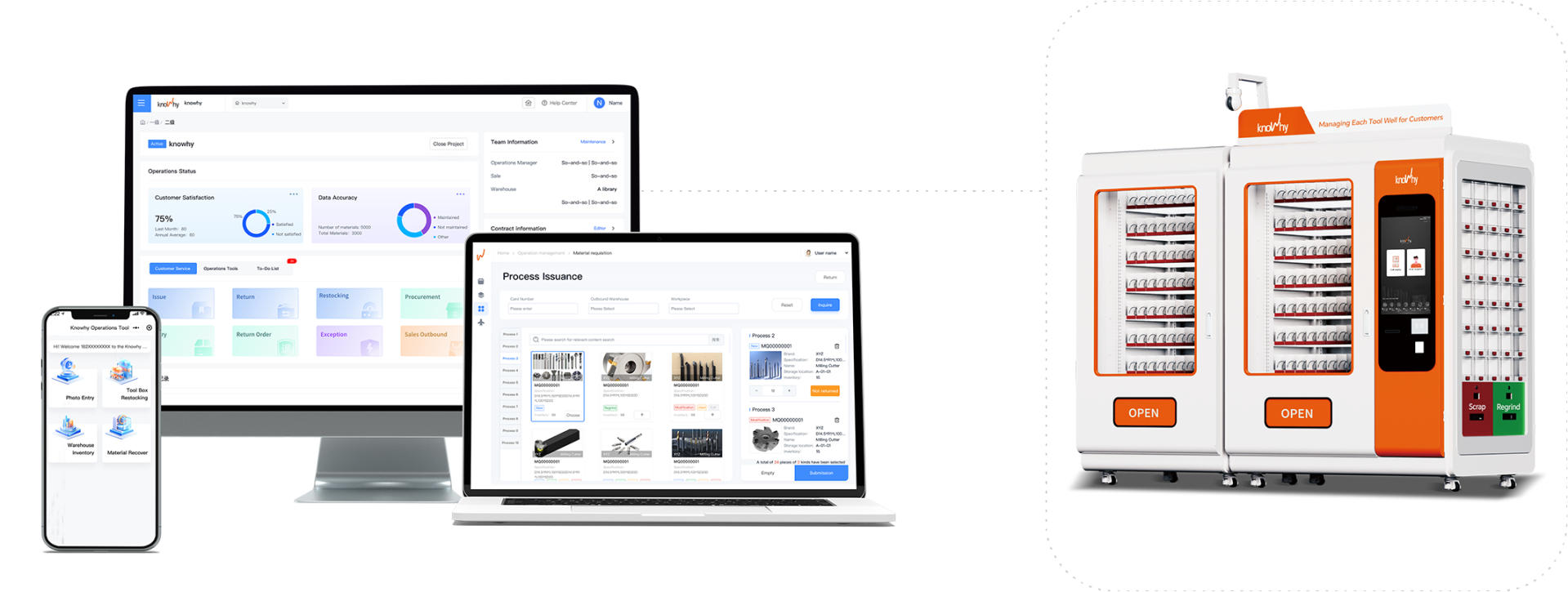

Knowhy’s intelligent tool management system is exactly that entry point:

It transforms tools from mere “consumables”

Into data units that can be sensed, analyzed, and optimized

Through hardware–software collaboration, real-time tracking, and traceable analysis, Knowhy helps manufacturers:

Understand cost flows

Improve usage efficiency

Predict tool life patterns

From “picking tools” → “calculating tools” → “understanding tools,” digital tool management is giving enterprises the agency over production elements.

02 Institutional Innovation Must Let Data Become Productivity

The 4th Plenum emphasizes promoting the deep integration of technological innovation and industrial innovation.

The focus is not “innovation” per se, but “integration” — technological achievements only become real productivity when embedded into industrial operations.

Tool management is a microcosm of that. Before digitized systems, tool usage relied on experience and manual management. Once data streams are opened, enterprises can:

Use statistical patterns to optimize procurement timing

Use algorithmic models to forecast tool life

Use digital twin simulations for cost–benefit analysis

What Knowhy is doing is not only improving efficiency, but helping enterprises build institutional capability for data management.

This is the real path for new quality productivity in manufacturing: turn data into an institutional asset, and make improvement a replicable capability.

03 From Experience to Intelligence — A Mandatory Course for Every Factory

In factories, experience used to be the most valuable resource. But today, experience must be digitized, and knowledge systematized.

In over a hundred machining sites Knowhy has visited, we observed transformations:

Tool changes once based on a veteran’s “feel” are now logged and optimized by system

Inventory once estimated by eye is now computed by algorithm

Cost analysis once relegated to month-end reports is now visible in real time

This shift is not just a “management upgrade,” but a cultural evolution of manufacturing — from “humans deciding” to “data guiding,” from “relying on experience” to “leaning on systems.”

04 The Future of a Manufacturing Powerhouse Depends on Data-Savvy Factories

The modernization blueprint drawn by the Plenum must finally find root in production lines and factories.

Digital tool management is a key variable in those micro links:

It transforms production from “manual supervision” × “labor intensity”

Into “humans + systems” × “collaborative intelligence”

It redefines underlying manufacturing efficiency, and gives enterprises internal drive for continuous optimization

Make management more scientific; make manufacturing more intelligent.

This is not just Knowhy’s mission — it’s China manufacturing’s mandatory question in the new era.

Summary

Institutional innovation sets direction, technological innovation outlines the path, industrial innovation makes it practical. In this deep change from policy to production, every seemingly small digitized practice helps build a new foundation for Chinese manufacturing.

💡 With Knowhy, tool management generates value — and manufacturing becomes more future-oriented.

+86 512 6938 3264

+86 512 6938 3264