Knowhy is an enterprise dedicated to providing customers with tool management and technical services. We take it as our responsibility to solve various processing technology problems, constantly innovate and improve our technical level, and provide customers with better services.

The case shared today is a targeted solution to the burr problem encountered during the machining process of automotive fuel rail installation brackets. By modifying the contour of the chamfering tool, the machining difficulty was effectively improved, and the machining efficiency and product quality were enhanced.

01

Description of workpiece condition

The main processing material of this workpiece is stainless steel, and the processing difficulty lies in the large number of connecting holes, which makes the processing holes prone to burrs. How to effectively improve the burr problem?

In this case,Knowhy has developed effective improvement measures to address the material specificity and the difficulty of deburring holes in automotive fuel rail installation brackets.

Image | Processing workpieces

02

Nuo Er provides a solution

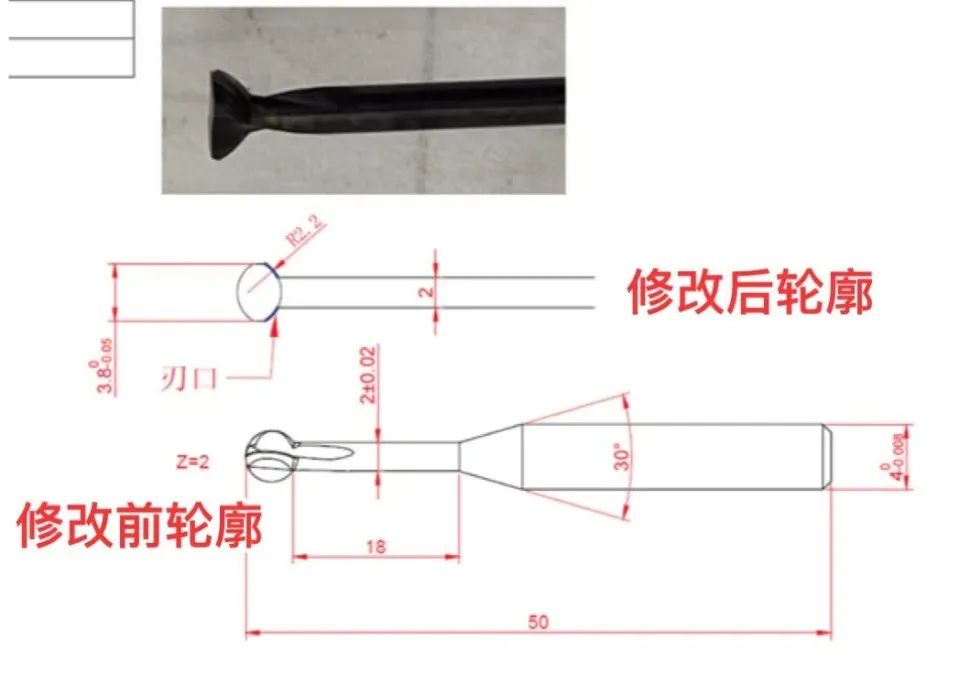

Knowhy has developed a key improvement plan for technical engineers to address the issue of burrs: modifying the contour of the chamfering tool.

Before the implementation of the plan, the customer had been using standard ball head cutting tools. When removing burrs, the tools were flipped back and forth for processing, which not only wasted processing time but also had little effect on deburring.

After in-depth observation and testing of the on-site working conditions, the technical engineer ofKnowhyproposed to elongate the chamfered arc line and modify it into a contour chamfering tool, replacing the conventional ball head tool for deburring.

Image | Tool Drawing

03

Optimization results

Due to the change in the contour line of the tool, deburring can be solved by machining the tool once, which not only effectively solves the problem of burrs, but also saves ⅓ time, greatly shortens the machining time, and improves the machining efficiency.

At the same time, modifying the contour of the chamfering tool also reduces the grinding surface of the tool, improves the service life of the tool, reduces the number of tool replacements, and effectively reduces costs.

Not only that, Knowhyalso has a deep understanding of the customer's production environment, helps customers with normalized operations, and provides comprehensive after-sales service to ensure the stability and continuity of the customer's production process.

04

conclusion

The continuous development of the machining industry requires higher processing standards, including higher quality, more precise manufacturing, and faster production speed.

As a company specializing in one-stop tool management services, Knowhy has fully leveraged its advantages by providing technical services to customers with a professional perspective and innovative thinking, helping customers solve various processing problems and winning trust and praise with professional strength.

+86 512 6938 3264

+86 512 6938 3264