During the machining process, challenges, innovations, and breakthroughs in the field of technology are unfolding in various machining industries.

With the deepening cultivation in the field of industrial technology services, Nuo Erwei's technical team has also accumulated countless processing experiences and cases.

What we are going to share today is how to meet the machining requirements of pillar holes under high smoothness requirements, thereby effectively improving the stability and efficiency of the machining process.

01

Overview of the workpiece

A 4-cylinder diesel engine product at a certain customer's site is equipped with 8 valve lifters, among which the lifter holes serve as precision assembly holes, requiring high cutting requirements for the cutting tools.

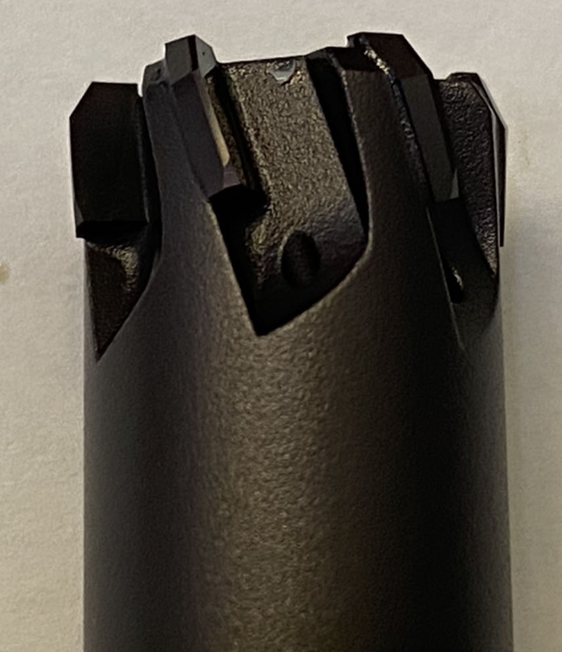

Image | Workpiece Processing Position

Specific processing difficulties

① High requirement for hole wall smoothness: smoothness Ra0.8;

② The interference length of machining tools is relatively long, which can lead to problems such as poor tool rigidity, difficulty in maintaining straightness and runout;

③ High processing efficiency requirements, fast processing parameters (S3200 F3800), and high tool wear resistance requirements;

④ During the machining process, minimizing the cost of tool usage as much as possible... These are a series of on-site issues that exist with the workpiece.

02

Solution and optimization results

In order to effectively solve these difficulties and improve processing efficiency, Nuo Erwei's technical engineers provided a comprehensive solution through on-site investigation and combined with the specific needs of the enterprise for cutting tools:

Firstly, regarding the requirement for high smoothness:

· ·Nuoer has chosen a more wear-resistant metal ceramic material, which has low affinity with the processed material and is less prone to chip formation, thus ensuring the smoothness of the workpiece after processing.

· The cutting method adopts a left-handed chip removal method with the tool itself having a squeezing effect during the machining process, aiming to improve the surface quality of the machined hole wall through the movement of the tool inside the hole.

Secondly, regarding the issue of interference length:

· The blade holder and handle flange face adopt an integrated design, and a smaller flange plate is used on the handle to reduce the design. At the same time, the handle has an adjustable design, effectively ensuring the straightness of the tool and reducing the tool jumping phenomenon.

· The tool head adopts a manufacturer's connection interface, which is low-cost and quick to change.

Image | Extension rod with blade design

To improve the wear resistance of cutting tools:

· Design the cutting tool as a double step structure, with expansion and hinge functions on one tool. Cutting 0.2mm per tooth enables the hinge cutting of the metal ceramic to have cutting function, avoiding the squeezing phenomenon of the tool and thus extending the service life of the tool.

· In terms of process, Nuoer adopts a drilling, expanding, and reaming process arrangement to meet the requirements of hole position accuracy. The main deviation angle of the hinge cutting tool is designed to be 30 °, so that the tool can better enter the hole for cutting during the cutting process, avoiding the occurrence of tool vibration.

Finally, the cost reduction requirements during the use of cutting tools:

· Effective grinding and secondary utilization. When grinding the tool, try not to damage the back corner of the base as much as possible, protect the tool body, and increase the number of times the tool needs to be ground.

· Through effective testing and performance analysis, Nuoer has further improved the tool life, reduced tool costs, and achieved the maximization of tool processing life.

03

conclusion

Through the above technical services, Nuo Er has comprehensively ensured the quality of processed products, stabilized existing production, and implemented tool optimization and substitution, improving overall cost-effectiveness. This series of solutions effectively addresses many challenges in the machining of tappet holes and provides customers with efficient and reliable technical support.

+86 512 6938 3264

+86 512 6938 3264