Introduction:

Is it impossible to accurately control the lifespan of cutting tools?

Do we often encounter situations where the tool life does not meet the standard when producing knives?

The unstable lifespan of cutting tools affects production efficiency and processing quality, and may even increase production costs.

Have you encountered these problems before?

How to evaluate the reasonable lifespan of cutting tools?

In the machining industry, evaluating the reasonable lifespan of cutting tools is crucial as it can help control production costs, improve production efficiency, and ensure product quality. Generally speaking, the reasonable lifespan of a tool can be evaluated through the following dimensions:

Increase cutting time: Record the total running time of the tool during the cutting operation, usually in minutes. By comparing the running time with the tool life guidance provided by the tool manufacturer, the reasonable life of the tool can be evaluated. If there are no abnormalities in the machining performance after reaching the set time, the normal time can be increased by 5% -10%, and the reasonable time life can be evaluated by cycling several times.

Tool wear and damage: Regularly inspect and evaluate the degree of tool wear and damage. If the surface wear of the tool is excessive, there are obvious notches on the cutting edge, or cracks begin to appear on the cutting edge, it may mean that the tool needs to be replaced, and it also means that the tool has reached the end of its life under the current machining parameters, and this life is recorded in terms of the number of workpieces and machining time.

Cutting force and power consumption: Evaluate the condition of the tool by monitoring changes in cutting force and power consumption. When the cutting tool is worn or damaged, the cutting force and power consumption usually increase (usually called cutting resistance, at which point the cutting resistance will increase and there will be a feeling of being unable to cut, specifically manifested in the increased sound of the machine tool or the vibration of the machine tool spindle). Regularly measuring cutting force and power consumption and comparing them can help determine when the tool needs to be replaced.

Product quality: Tool wear or failure may have a direct impact on product quality. By monitoring the dimensional accuracy, surface quality, and other key indicators of the product, it is possible to evaluate whether the cutting tool has affected the product quality. If quality issues are found, it may be necessary to consider replacing the cutting tools.

How can we do a good job in tool life management?

As a professional tool management service provider, Nuo Erwei has unique advantages in tool life management.

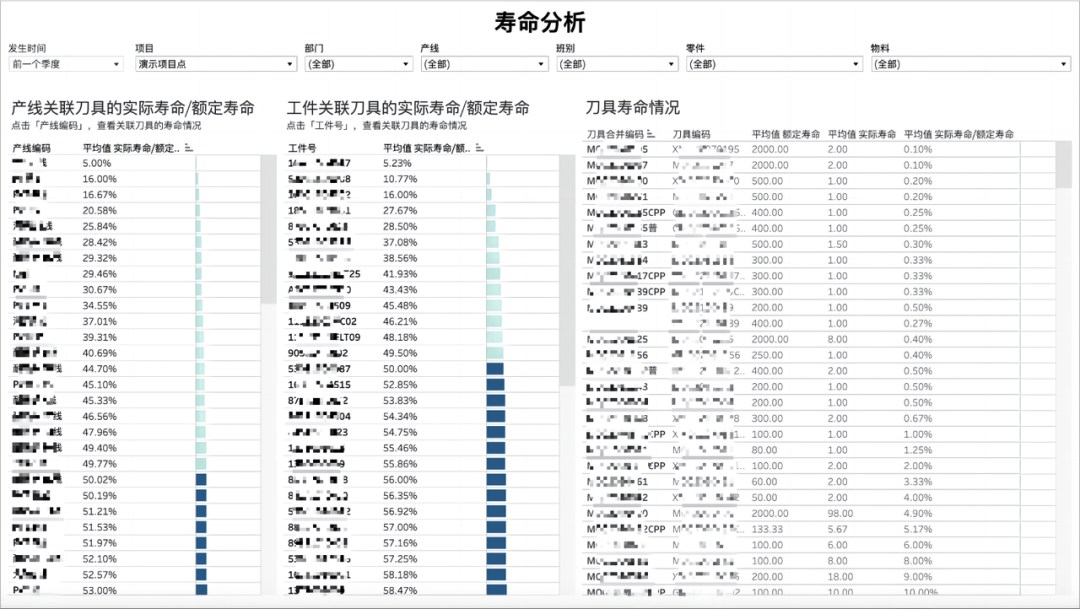

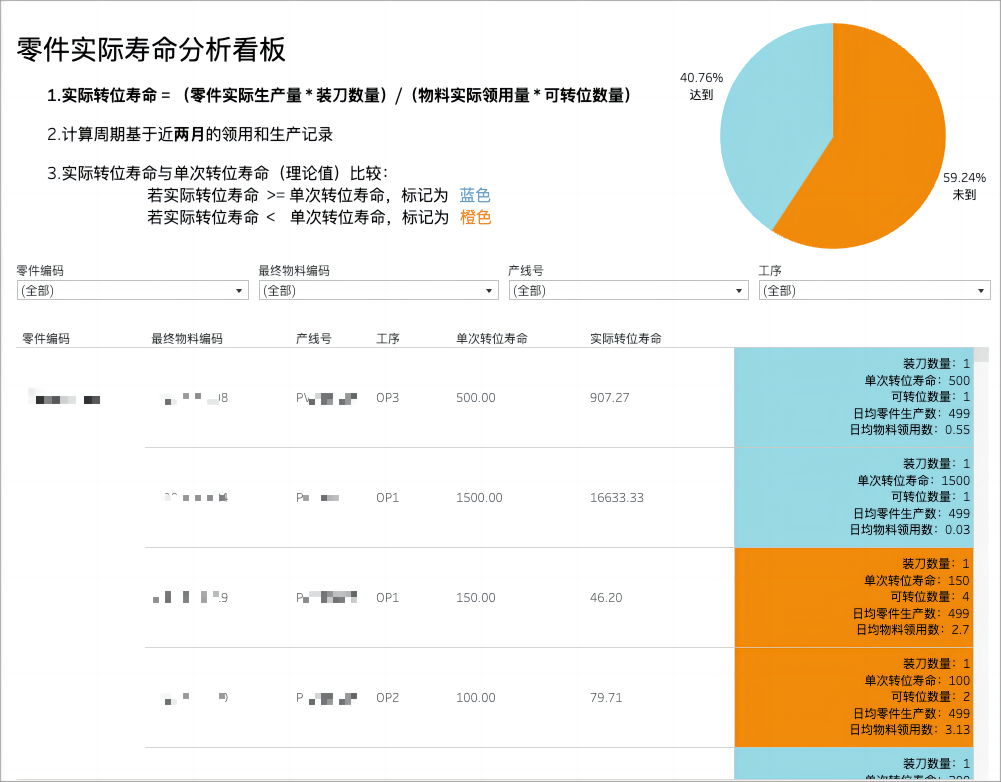

·Part processing technology standards, automatic collection of multi-dimensional data information

1) Based on actual machining scenarios, establish process standards for part machining and associate the tool information used in each process, namely the tool BOM of the part;

2) Establish standard values for tool life, collect data while changing tools, performing abnormal machining, and optimizing replacement, and continuously conduct dynamic management.

·Record and solve every issue of life expectancy not being reached

Identify and address the core issue of insufficient lifespan. After years of accumulation and customer practice, Suzhou Nuoerwei's tool management system has truly implemented the ability to continuously improve tool life, from process standards to dynamic positioning of life, and statistical analysis of abnormal states.

To summarize

Effective tool life management is an important part of tool management in machining enterprises, which is one of the ways to improve quality and efficiency, and effectively reduce the comprehensive application cost of tools.

+86 512 6938 3264

+86 512 6938 3264