On the machining front line, another challenge arises.

Reamer tip chipping, poor surface finish, and short tool life — this cut tests not only the tool itself but also the wisdom of process optimization.

Knowhy now issues Hero Challenge #24, inviting global cutting tool manufacturers and machining solution providers to join us in tackling this reaming challenge.

🔍 Challenge Details

Part Information

Part Name: Automotive Component

Material: Q355 (HB250)

Machining Process: Finish reaming D28.02H8

Machine Tool: Vertical Machining Center

Tool Type: D28.02 Reamer

Feed Rate: F300–400 (External Coolant)

Tool Life: 1200 pcs

(Part photos available upon request.)

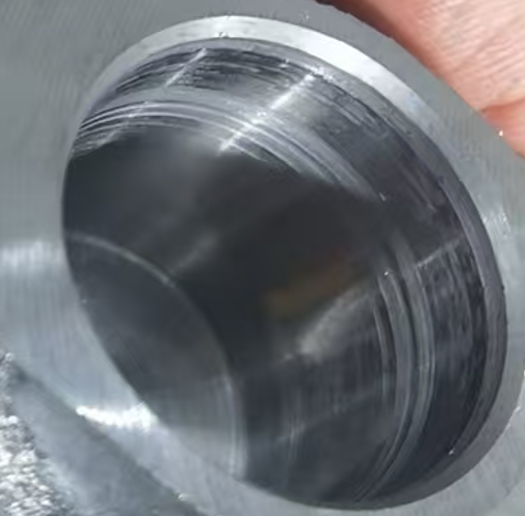

⚙️ Current Machining Issues

Reamer tip chipping

Poor surface finish

Tool life remains unstable and short

🎯 Challenge Requirements

Surface quality and appearance must meet drawing specifications.

Maintain current machining efficiency — cycle time should not increase.

Extend tool life and ensure long-term process stability.

💡 You may optimize based on the existing process or propose an entirely new machining solution — innovation is welcome!

💼 Collaboration Benefits

✅ Supply Opportunity

If your proposed solution passes the validation test, your company will be granted a minimum one-year supply qualification.

✅ Industry Recognition

Outstanding solutions will be featured through our industry channels, helping you enhance brand reputation and technical visibility.

📩 How to Participate

Submit your company’s machining solution via:

Email: Marketing@knowhy.com.cn

Tel: +86-177-0157-7102

We welcome participation from global tool manufacturers, machining solution providers, and R&D teams.

Whether your strength lies in process improvement, innovative tooling, or breakthrough machining concepts —

if it enhances efficiency and quality, we want to see it.

🕒 Challenge Duration

Long-term open call.

🧠 Evaluation Process

Our expert panel — including Knowhy’s technical team and customer engineers — will evaluate all submitted solutions based on innovation, practicality, and feasibility.

Winning solutions will not only gain tangible business opportunities but also be showcased across the industry, amplifying your visibility and partnership potential.

✨ Knowhy Insight

In machining, there is no standard answer.

Every process optimization and every technical breakthrough pushes the boundaries of manufacturing forward.

If your company has the experience, ideas, and technology,

we invite you to take the challenge — and together, create a new benchmark for efficient reaming.

© All technical information and related content mentioned in this article are the property of Knowhy and are provided for reference only. Unauthorized commercial use is prohibited. Knowhy reserves the right of final interpretation and will pursue legal action in case of violations.

+86 512 6938 3264

+86 512 6938 3264